WORKING WITH STYROFOAM

June 29, 2015

Today I'm going to show you a couple of techniques for working with EPS, or Expanded Polystyrene. This is the white foam (commonly referred to as Styrofoam) that is used as packing material for electronics and appliances.

EPS is super easy to come by-chances are you've got some laying around the house right now. It is also available in craft stores and comes in sheets, blocks, and various other shapes. It is great for making lightweight props, lining cases, or craft projects.

The best way to cut EPS is with a hot wire foam cutter. I picked this one up at a craft store; I think it was around $30. It is basically just a power supply and a wire that heats up to several hundred degrees. This makes a nice clean cut in the foam and as far as I know the only byproduct is a bit of carbon dioxide so it's safe to use indoors. There are much nicer units out there-if you find yourself doing a lot with foam you may want to invest in a professional grade tool. Please keep in mind that these hot wire cutters are for WHITE EPS ONLY; they should NOT be used to cut EVA or Polyurethane foam. You will not get a clean cut with these other foams but you will get some nice toxic fumes.

As always, practice good shop safety and be sure to follow the directions given by the manufacturer.

LET'S GET CUTTING!

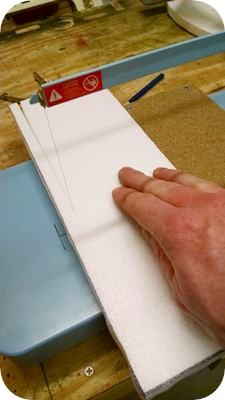

TECHNIQUE #1 - MAKE A RIP FENCE

I built a handy little guide for cutting straight foam blocks by gluing and screwing some particle board scraps. The fence straddles the base of the cutter and uses a friction fit. You could also use a bar clamp if needed. I use this as a guide to make nice straight cuts.

Slow and steady wins the race. The thicker the material, the slower you should go.

Not a bad cut. You may notice some slightly jagged lines on the cutting edge-this is caused by pausing while pushing the material through the wire. If your foam piece becomes stationary during cutting, the hot wire will continue to eat away material. For best results, maintain a constant speed and pressure.

TECHNIQUE #2 - CUT (NEARLY) PERFECT CIRCLES

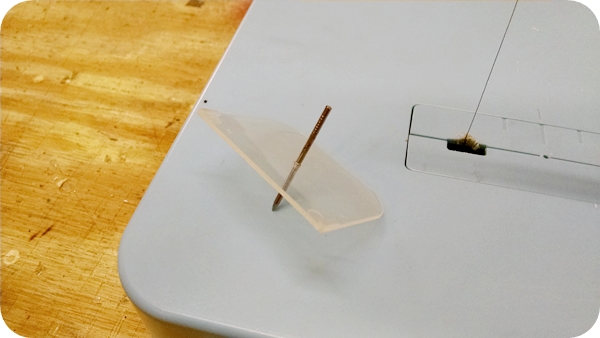

I've never been able to build a jig that cut laser-perfect circles, but we can get close. THIS WILL REQUIRE MODIFICATION OF YOUR TOOL. DO SO AT YOUR OWN RISK. The first thing to do is drill some small holes in the cutting base at the ruler marks. (make sure you don't go in too deep and hit the wires inside-we just need to go through the very top of the plastic). These holes will be the guide for our circle radius.

The next thing you'll need is a small finishing nail and a piece of thin plastic. I used a divider from one of my many plastic storage bins. Push the nail through the center of the plastic, then use a wire cutter to snip the nail head.

Insert the nail in the hole that marks the radius of the size circle you want to cut. Remember, the radius is half the diameter. So for an 8 inch circle you would need a 4 inch radius and so on. Hold your handy radius pin in place with tape and you're ready to make a circle!

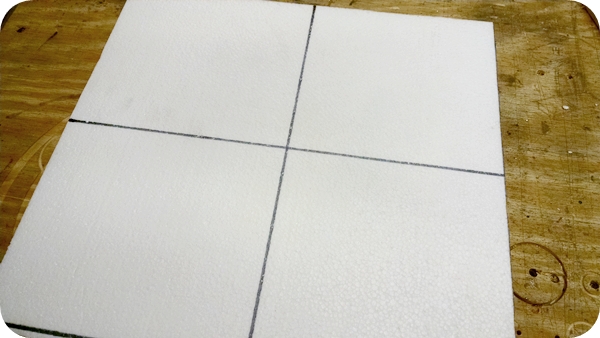

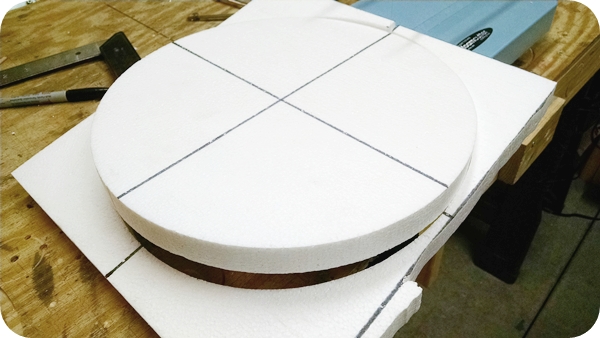

Cut a square of foam just a bit bigger than the diameter of your circle. About an inch all around should do. If the square piece is too big to fit inside the arm of the cutter then cut off all four corners like so:

This is the only time I will advise you to cut corners.

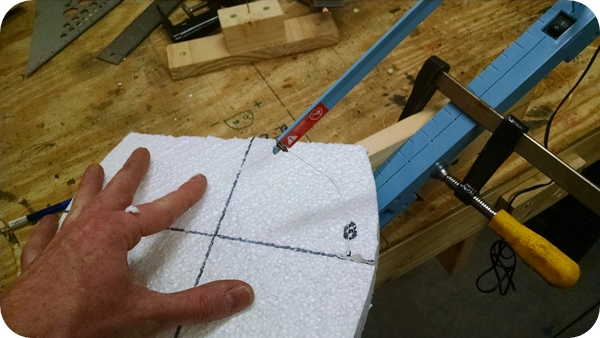

Turn on the foam cutter (it usually only takes about 10 seconds to reach operating temperature) and push your foam piece into the wire. Go in about half an inch and then push the foam down onto the radius pin. Now slowly and steadily turn the foam piece round. It will pivot on the guide pin and form itself into a nice circle!

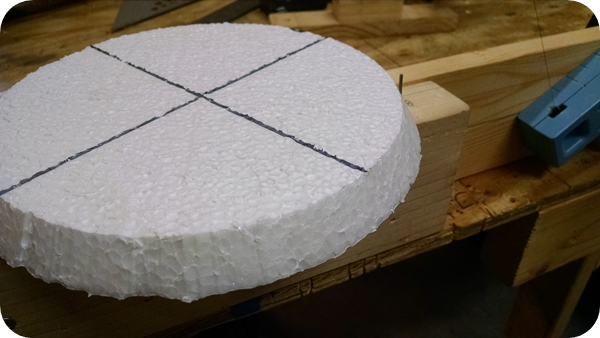

Viola! A styrofoam circle is yours. Wasn't that easy?

But wait...there's more!

TECHNIQUE #3 - CUTTING LARGE CIRCLES

You may have noticed that the L-shaped arm on the cutter will only allow you to cut a circle with a radius up to about 5 inches.

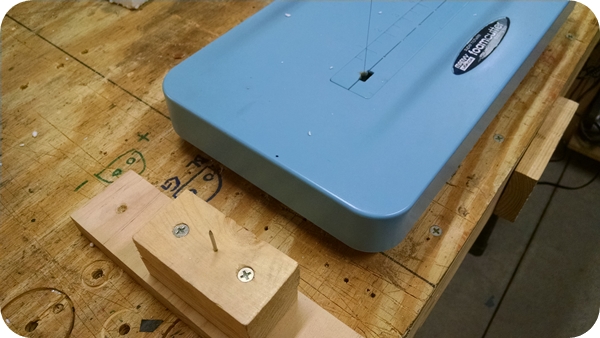

Well, I've got a solution for that.

For large diameter circles, we need to work from the left side of the cutter. I made up a second guide pin that is the same height as the cutting base. This guide can be moved around and clamped to my work table. With this setup we can conceivably cut circles up to 4 feet in diameter!

With bigger circles it helps to mark out your center. This allows you to stay on-axis when pushing the foam block into the wire. If you get your block off center you can run out of room and end up with a partial circle. Ask me how I know :)

The process is the same as before.

This one came out nice! I used a thicker, denser foam this time.

Moving on...

TECHNIQUE #3 - BEVELED EDGE CIRCLES

So, it's time to make another jig! On of the cool things about this particular foam cutter is that the bow detaches from the base to do freehand cutting. This also enables us to make some cool beveled cuts. This is gonna look a bit crazy, but hang with me here. I swear it works!

I'm using a 60° square to set my desired angle. I then clamp the cutting tool to a 1"x4" board. Really you can do any angle you like but we'll get to this in a bit.

OK, here's what the jig looks like. You can see the cutting tool mounted at an angle (the small block underneath helps hold it in place). On the left is a 2x4 with holes drilled out to hold our handy guide pin (finishing nail as before). See where I'm going with this? The technique is the same as before, we're just combining two operations (circle and bevel) and making a compound cut.

Easy stuff, right?

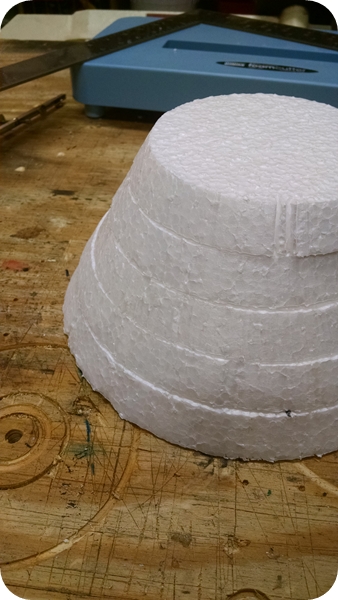

Alright! We now have a circle with a 60° bevel. This can come in very handy, say, if we wanted to make a cone shape...

Cutting smaller and smaller beveled circles and stacking them will eventually result in a cone. The steeper the angle, the narrower the cone will be. This is the same technique I used to make the drill head for my Dig Dug costume.